Our products deliver sustainability and a circular economy

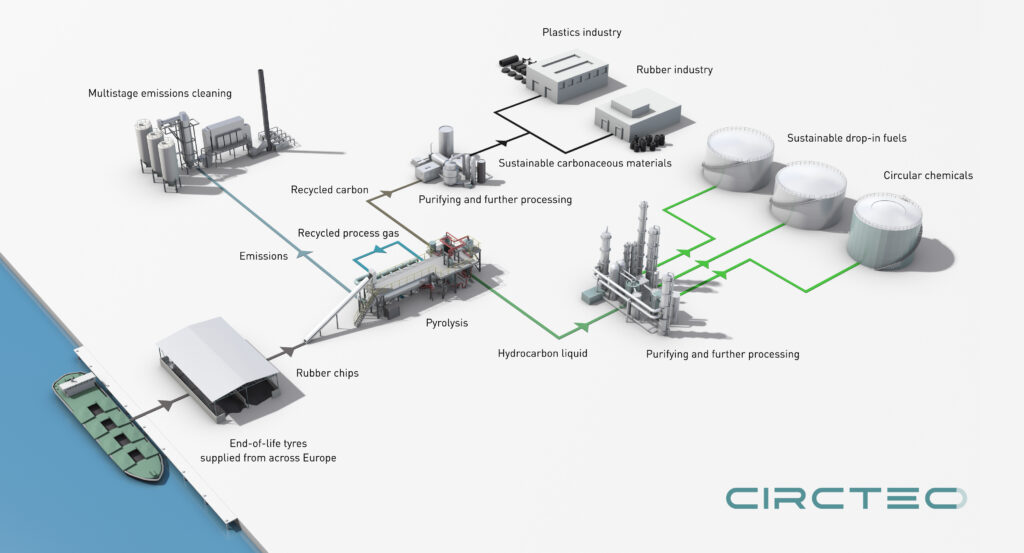

CIRCTEC produces sustainable drop-in fuels and circular chemicals from the vast amount of end-of-life tyres that are disposed of every year.

For example, we extract carbon black, a fossil fuel based chemical that is present in almost every black product in our lives, and we create a recycled substitute.

We are also the world leader in refining and producing product grade sustainable fuels and liquid chemicals from the natural and synthetic rubber content of end-of-life tyres.

Since 2009 we have developed our processes through cutting edge technologies and smart chemistry; to contribute to a cleaner, more sustainable world.

Technology

feedstock: end-of-life tyres

feedstock: end-of-life tyres

sustainable carbonaceous materials

sustainable carbonaceous materials

sustainable drop-in fuels

sustainable drop-in fuels

Our raw material is waste that would otherwise be burned and landfilled. Tyres are incredible – composite technological products of unparalleled toughness, full of valuable chemicals which took a lot of CO2 emissions to make.

In a world that urgently needs to decarbonise, it is a tragedy to see this resource wasted and even more CO2 emitted to dispose of it. But the supply of waste tyres today is far bigger than the available capabilities to recycle them – and the flow of this waste is getting bigger and bigger every year.

A technological problem needs a technological solution. Over the years we have invested heavily in developing solutions to each and every challenge involved in turning that end-of-life tyre into CO2 emissions savings.

Large CO2 emissions reductions for in-demand products

The CIRCTEC process

State of the art environmental compliance

Our plant processes have an unrivalled focus on energy efficiency and control of emissions.

We power our plant operations off the gases produced in our process, and we integrate the use of renewable energy, avoiding the need for use of fossil fuels. Nothing is wasted and we never flare process gas. We recover heat and reuse it and we make use of wasted energy from other neighbouring companies. This integrated approach to energy efficiency is one of the ways we generate exceptional CO2 savings from our products.

We also operate the most sophisticated multi-stage emissions control systems, purifying our emissions to levels many times lower than conventional plants. We don’t just reduce CO2 emissions, we also create emissions savings of other pollutants.